(강하넷)

KanghaNet

QUALITY MANUAL

Section II - 01 Section Rev.: A Rev. Date: 04/ /04 Section Page 1

Quality Management System

1.0 Scope

The KanghaNet quality system is developed and maintained as a means of ensuring that product conforms to specific requirements according to certain commercial, and international standards. The goal of having a company wide quality system is to define, document and improve the business processes that insure the conformity of the end product with customer requirements and the organizational growth and innovation. When these processes are subcontracted, KanghaNet has in place an organization, means and tools to ensure control over these processes.

Currently the Quality systems and manuals are site dependent and the audits are performed by the site. In the near future a global system and auditing will be introduced. There is a difference in coverage of the different systems. TS16949 is applicable to all sites.

The quality activities described in this manual meet, but are not limited to, the following:

ISO 9001/2000 which defines the fundamental quality system expectations of automotive customers.

ISO 9001/2000, an international set of guidelines for managing a quality system.

ISO/TS 16949:2002(E) which defines the quality management system requirements for the design and development, production, of automotive related products.

2.0 Purpose

The Quality Manual serves as the internal top-level document in a hierarchy of system requirements, procedures, and work instructions, which together define the KANGHANET Quality System. The Quality manual describes in short or gives reference to systems related to sales, marketing, product and process development, manufacturing, testing, delivery and subcontracting worldwide. These proprietary procedures are found in actual working documents that are available for customer review and/or regulatory authorities identified by the customer.

The Quality Manual gives a comprehensive overview of the business processes and relationships at company and departmental level. The quality manual itself is non-proprietary and is available for distribution to employees, customers, government representatives, vendors, subcontractors and assessment organizations.

3.0 Reference Documents

100 - Quality Management System Requirements

101 - Management System Requirements

102 - Resource Management System Requirements

103 - Product Realization and Process System Requirements

104 - Measurement, Analysis, and Improvement System Requirements

105 - Customer and Market Focus System Requirements

ISO 9001:2000 - Update of the ISO9001/1994 standard for quality systems.

ISO/TS-16949:2002(E) - Technical specification providing for the development of a quality management system that provides for continual improvement, emphasizing defect prevention and the reduction of variation and waste in the supply chain for automotive customers

.

Approved by: Approved by:

4.0 Glossary

Glossary items are defined in the body of the manual.

5.0 General Requirements

5.1 Responsibilities

The contents of the quality manual are reviewed and approved by PRESIDENT/ CEO, in conjunction with the approval of KANGHANET Technical Review Board, before publication of each revision. The responsibility to integrate KANGHANET's quality principles into the organizational structures resides with the President/CEO of the company and his staff.

5.2 Training and Certification

All employees of KANGHANET are required to be certified to this document.

5.3 Records

No records are generated by this document. Records are generated by the various procedural and work instruction documents and are governed by those documents.

6.0 Quality Management System

6.1 General Requirements

The PRESIDENT/ CEO of KANGHANET have the executive responsibility to define and document the company's quality policy statement. This policy is implemented through the company's Quality System, which provides direction, in the quest for organizational growth and continuous improvement of process, product, policy and procedures. KANGHANET is committed to this policy and requires that it be communicated, understood, implemented and maintained at all levels of the company.

When these processes are subcontracted, KANGHANET uses its supplier management system to ensure control over these processes

Email : kangha@daum.net

'문서 및 자료 > 【 문서참고자료 】' 카테고리의 다른 글

| 잔토 운반거리별 단가산출서 (0) | 2022.07.22 |

|---|---|

| 문서 및 데이터관리 지침서 (0) | 2022.07.20 |

| 반출 및 납품지침서 (0) | 2022.07.13 |

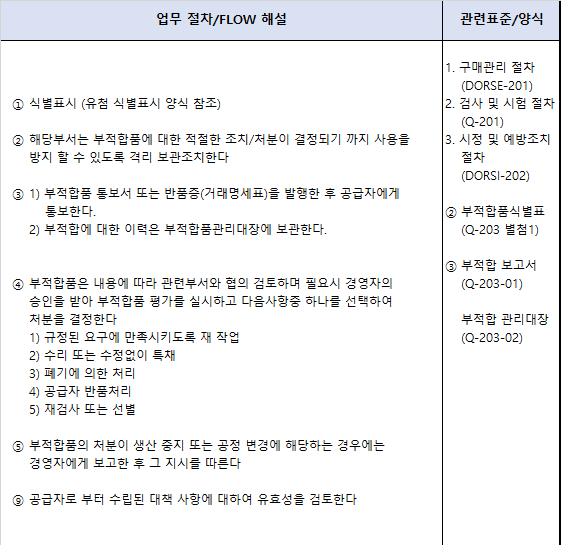

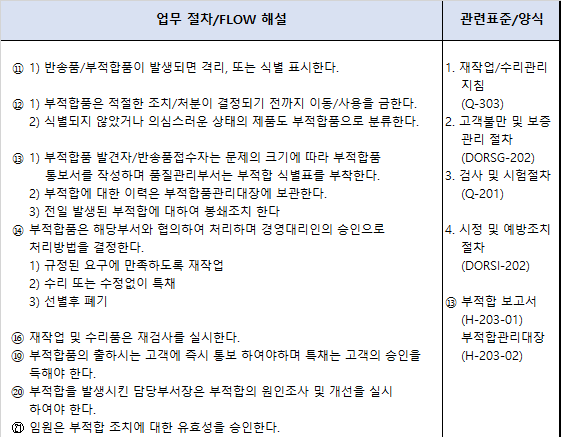

| 부적합품관리 절차서 (0) | 2022.07.12 |

| 검사 및 시험프로세스 (2) | 2022.07.09 |